Sintered bronze parts are rigid, temperature resistant and high strength parts formed through the process of sintering, or powder metallurgy. Used in applications for shock absorbers, home appliances, automobiles and as well as most commonly as bearings or bushings, sintered bronze parts can be produced in large quantities with consistent properties and sizes. Powder metallurgy uses a number of different metals including aluminum, copper, nickel, brass, steel, stainless steel, nickel and titanium in the fabrication of metal powder parts. Read More…

Since 1967, PSP has been a leader in small, intricate custom powdered metal parts for a wide range of industries, such as Sports & Recreation, Power Tools, Industrial Equipment, Oil & Gas.

Liberty Pressed Metals is a designer and producer of Powder Metals (PM) components for use in various industries, such as automotive, lawn and garden, office equipment, power tool, home appliances, and more. Our process boost product strength, precision, and durability. We are ISO 9001: 2015 certified. Our quality management system assures top-quality sourcing of materials, as well as unmatched...

At Embassy Powdered Metals, Inc., we specialize in crafting high-quality powder metal parts that meet the exacting standards of a diverse range of industries. Our expertise lies in transforming fine metal powders into durable, precision-engineered components through advanced powder metallurgy techniques. We offer an extensive portfolio of products that includes complex shapes and intricate...

At MetalKraft Industries, Inc., we specialize in the art and science of powder metal parts, blending innovation with precision to deliver exceptional components. Our expertise spans the entire spectrum of powder metallurgy, enabling us to craft parts that meet the highest standards of quality and performance. We take pride in our ability to transform raw metal powders into robust, intricately...

Enhanced Sintered Products, Inc. has manufacturing experiences dating way back. Our innovated products offer quick turnaround on all orders. These items come in a wide range of materials including Bronze, Iron, Brass & Copper and Stainless Steel. We also offer various secondary services including part design, tooling construction, sintering, molding, and more! Contact us today to learn more about ...

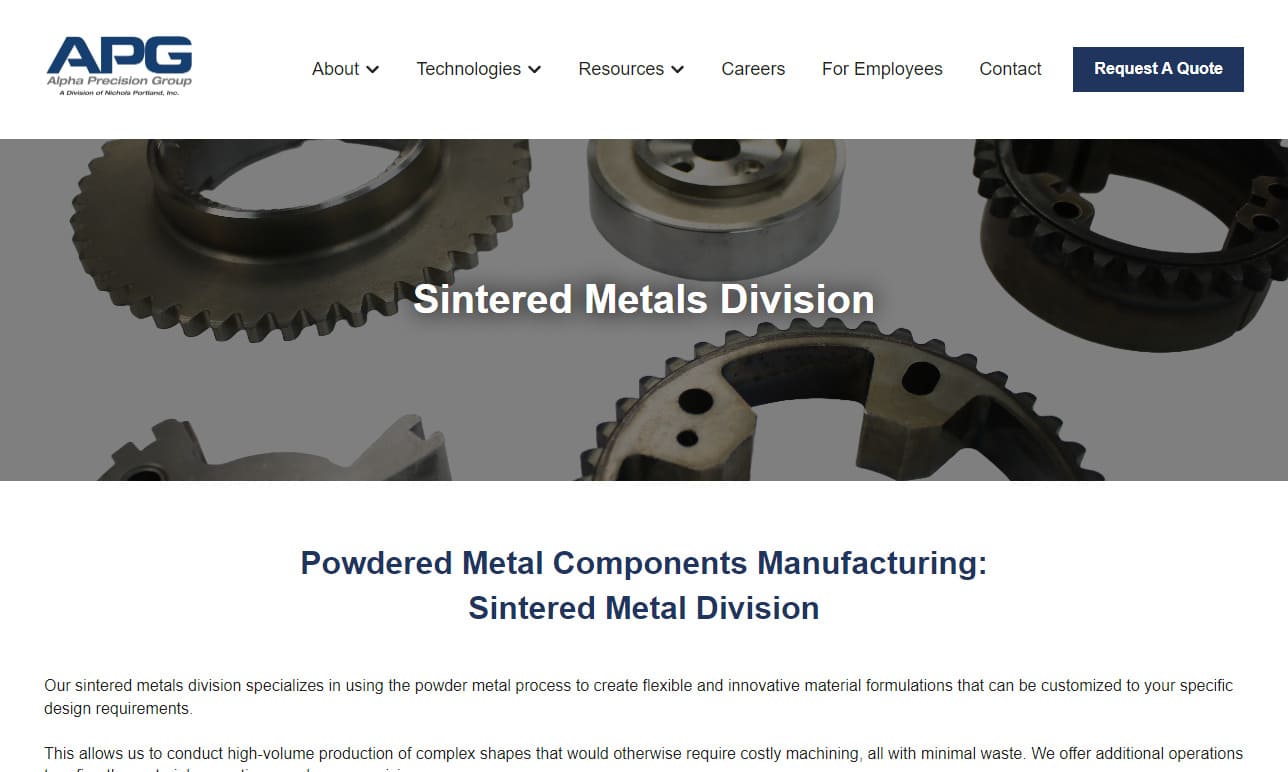

At Alpha Precision Group, we specialize in delivering high-quality powder metal parts tailored to meet the precise needs of our clients. Our expertise in powder metallurgy allows us to produce components with exceptional accuracy and durability, ideal for a range of industrial applications. We excel in creating complex and intricate parts that leverage the advantages of powder metal technology.

More Sintered Bronze Part Manufacturers

Bronze is an ideal material choice for the process of sintering as it is a non-ferrous metal is commonly used as a conductive material and its porosity allows lubricants, or air and liquids to pass through it. Through an effective sintering process, the properties of material strength, translucency and thermal conductivity are enhanced and because it is a simple process, most of the other physical properties of the metal are retained.

Sintered bronze parts are an economical manufacturing option, especially for large quantities of products as sintered metal parts can be fabricated repeatedly with close tolerances. The porosity of the parts can also be adjusted according to the intended application of the part and the desired level of flow.

The process of powder metallurgy has three basic steps. First, the metal, in this case, bronze or bronze alloy, is made into a powdered form. This can be achieved by a number of methods including grinding, chemical decomposition and the most common atomization. The metallic powder is then poured into a die or mold cavity and compacted under great pressure in order to adhere the particles. This occurs at room temperature. The metal part is then inserted into a furnace where the extreme heat fuses the metal particles together to form a rigid, high strength and porous component. This part of the process is called sintering.

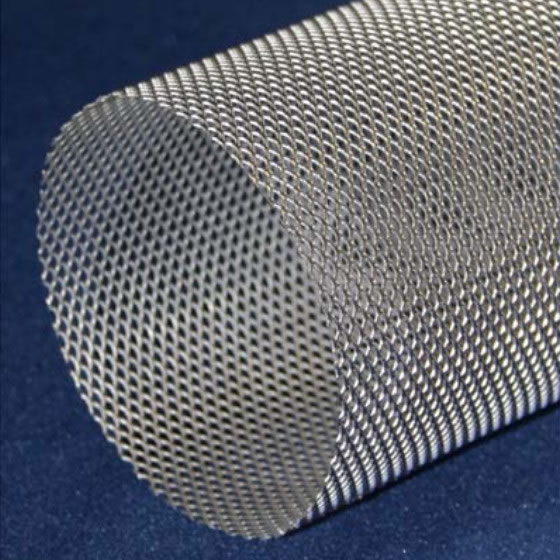

The resulting porosity of the sintered parts makes powder metal products especially useful in lubricating applications and as a result, bearings and wear plates are often fabricated from sintered bronze. These porous components are also commonly used to create filtration materials, especially for high temperature applications such as those in food or pharmaceutical industries. Bronze powder can also be used to coat the surfaces of wood, plaster, plastic and other metals in order to create a bronze-like finish. In cosmetics such as eye shadows or liners, finely powdered bronze is used to create a shiny appearance.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services