Metallic powders are used in powder metallurgy to create shaped components, which might be finished or semi-finished goods. Powder metallurgy, also known as press-and-sinter processing, is a more and more popular method for producing application-specific metal parts than conventional methods of forging at softening temperatures or casting from molten metal. Read More…

Since 1967, PSP has been a leader in small, intricate custom powdered metal parts for a wide range of industries, such as Sports & Recreation, Power Tools, Industrial Equipment, Oil & Gas.

Liberty Pressed Metals is a designer and producer of Powder Metals (PM) components for use in various industries, such as automotive, lawn and garden, office equipment, power tool, home appliances, and more. Our process boost product strength, precision, and durability. We are ISO 9001: 2015 certified. Our quality management system assures top-quality sourcing of materials, as well as unmatched...

At Embassy Powdered Metals, Inc., we specialize in crafting high-quality powder metal parts that meet the exacting standards of a diverse range of industries. Our expertise lies in transforming fine metal powders into durable, precision-engineered components through advanced powder metallurgy techniques. We offer an extensive portfolio of products that includes complex shapes and intricate...

At MetalKraft Industries, Inc., we specialize in the art and science of powder metal parts, blending innovation with precision to deliver exceptional components. Our expertise spans the entire spectrum of powder metallurgy, enabling us to craft parts that meet the highest standards of quality and performance. We take pride in our ability to transform raw metal powders into robust, intricately...

Enhanced Sintered Products, Inc. has manufacturing experiences dating way back. Our innovated products offer quick turnaround on all orders. These items come in a wide range of materials including Bronze, Iron, Brass & Copper and Stainless Steel. We also offer various secondary services including part design, tooling construction, sintering, molding, and more! Contact us today to learn more about ...

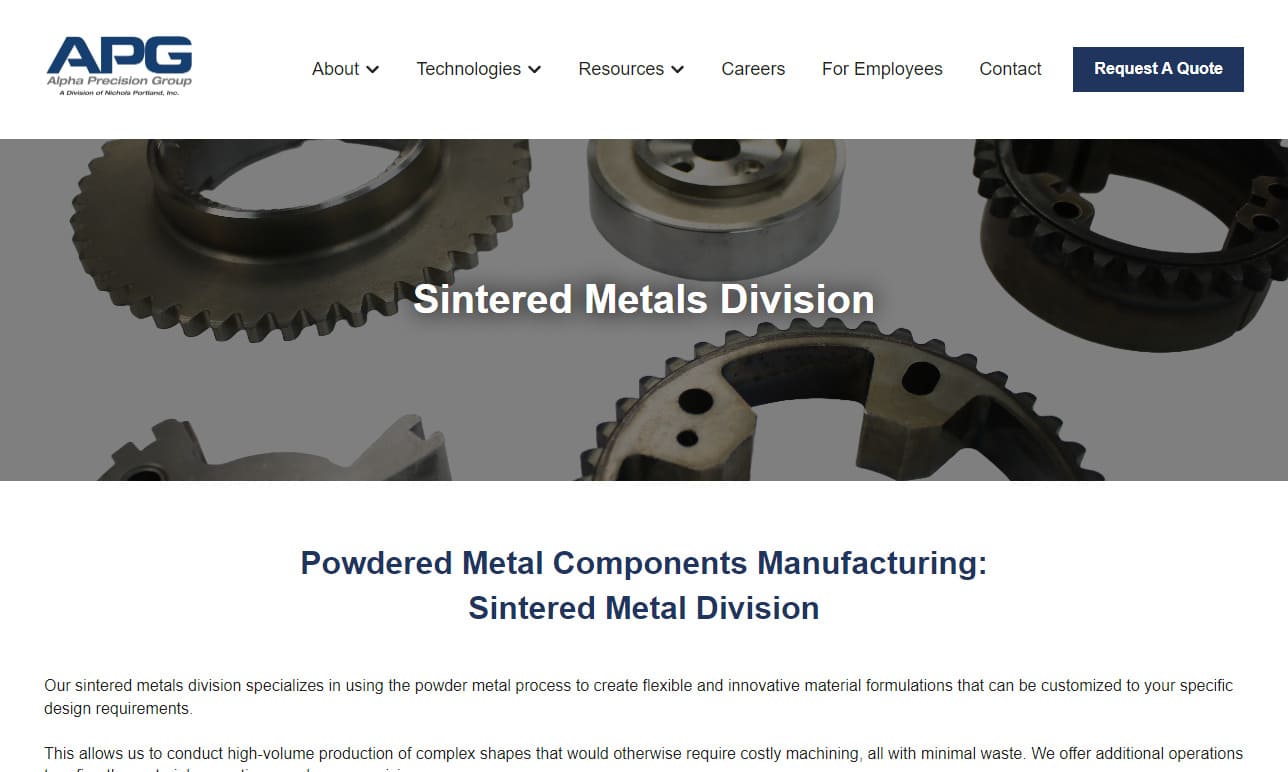

At Alpha Precision Group, we specialize in delivering high-quality powder metal parts tailored to meet the precise needs of our clients. Our expertise in powder metallurgy allows us to produce components with exceptional accuracy and durability, ideal for a range of industrial applications. We excel in creating complex and intricate parts that leverage the advantages of powder metal technology.

More Powder Metallurgy Manufacturers

Powder Metallurgy Design

Powder metallurgy warms metals to temperatures slightly below the melting point to compress and mix metal components. The granules maintain their unique features since there is no real melting. These metal powders can be elemental, partially alloyed, or pre-alloyed, enabling the development of incredibly distinctive and, more critically, extremely precise metal compositions. Steel, iron, bronze, copper, and other metals are frequently used in powdered metallurgy and other processes.

Powder Metallurgy Process

Powder metallurgy has three fundamental steps:

Stage 1

The main ingredient or materials must first be ground into powder. There are several tools available for this specific use. These mechanisms use pulverization, chemical reduction, electrolytic methods, mechanical alloying, atomization, and flaking, with the last two being the most popular, to turn stock metal into powder or finely divided metals.

Stage 2

After that, the particles are pumped into a compact die or mold. These give the final product's structure its structural restrictions. Powder metallurgy is skilled in producing complicated pieces requiring bends, projections, and depressions when the molds are executed.

Stage 3

Consolidation is the last step after the mold is filled. Different consolidation procedures might be applied, just like in the first stage. Cold isostatic pressing, uniaxial pressing, sintering, hot isostatic pressing, hot powder forging, and metal injection molding are all possibilities. Each entails a lot of pressure, but cold procedures must use much more pressure to achieve the cohesiveness that heated consolidation can achieve. A solid metal with varying characteristics and porosity is the result. In addition to the mechanisms employed, factors must be considered, including metal selection, completed product size, and number of items produced.

Applications of Powder Metallurgy

The following are some applications of powder metallurgy:

- Used to create porous components, such as filters

- Powder metallurgy creates some of the tungsten components used in jet engines.

- Moving parts for automobiles, such as piston rings, connecting rods, clutch plates, and camshafts

- A wide variety of soft and hard magnetic components

- Steel and diamond powder is used to make grinding wheels.

- Silver-infiltrated tungsten is used to make the nozzles for rockets and missiles.

- It is used to create intricately formed components, such as gears, that, when created using other techniques, necessitate machining.

- Metallic and non-metallic materials are combined to create electrical bushes for motors.

- Powder metallurgy creates components for devices like clocks, typewriters, calculators, permanent magnets, etc.

Advantages of Powder Metallurgy

Eco-Friendliness

An environmentally friendly production technique is powder metallurgy. Using powder metallurgy, an incredible 97% of the material needed to make the pieces end up in the finished product. There is virtually little waste and no scrap in powder metallurgy. The final component contains every powder particle used in the procedure. Not only is there less waste, but there are also huge financial savings as a result.

Flexibility of Materials Used and Products Created

In contrast to other procedures, powder metallurgy may combine and blend several metals and nonmetals into a product. With binding material, strange and unusual combinations can be combined to form a single part. Because powder metallurgy can blend many elements and crush them into a single shape, complicated metallurgical techniques can be avoided. Powder metallurgy can create any shape, including simple gears and complicated and complex designs. The technology's ongoing development is opening the door to various applications.

Almost Net Shape

Powder-metallurgy-generated parts and goods don't need any additional processing. Each component is almost a net shape, so finishing is unnecessary. Powder metallurgy components also offer incredibly high dimensional precision.

Available and Economical Raw Materials

Since a scarcity of resources can cause production to slow down or stop, the availability of raw materials is a persistent issue for manufacturing processes. Powder metallurgy can use readily available and reasonably priced raw materials. Metal powders are a relatively common everyday material easily accessible from numerous producers. As demand for powder metallurgy increases, more suppliers are creating fabrication procedures to satisfy it.

Repeatability in Product Accuracy

Every component in mass manufacturing must adhere to the dimensional specifications specified in the design, from the very first to the very last. However, the degradation during production in some procedures results in flaws and variations in the individual parts. Such mistakes are prevented by the consistency and reproducibility of the powder metallurgy process, which guarantees that each item has accurate dimensions.

Powder Metallurgy Limitations

- The price of the material in powder form is fairly costly.

- Complex products are challenging to manufacture because the metal powder does not flow well during compaction.

- The remaining porosity in sintered pieces gives them a rough surface.

- Due to the high cost of dies and equipment, this procedure is commercially viable only for large-scale production.

- Due to expensive dies, producing parts of large size and weight is highly expensive.

- Some metal powders are challenging to compress, and some are challenging to find.

- The density of the compact is not constant.

- Compared to other methods, powder metallurgy produces parts with low impact and fatigue strength.

- Powder metallurgy can cause health issues brought on by workplace air pollution.

Choosing the Correct Powder Metallurgy Company

To make sure you have the most beneficial outcome when selecting a power metallurgy company, it is important to compare at least 5 companies using our power metallurgy directory. Each power metallurgy company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each power metallurgy company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple power metallurgy companies with the same quote.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services